Rug Manufacturing Guide: Three different methods for rug manufacturing. The process of manufacturing rugs matters a lot as it decides the resulted rug’s durability, comfort, look, quality, etc. The carpets may be handmade or machine produced, and the main manufacturing techniques used by the rug manufacturing Guide include Hand-knotted, Hand-Tufted, Machine-made. Best rug manufacturers USA.

Rug Manufacturing Technique

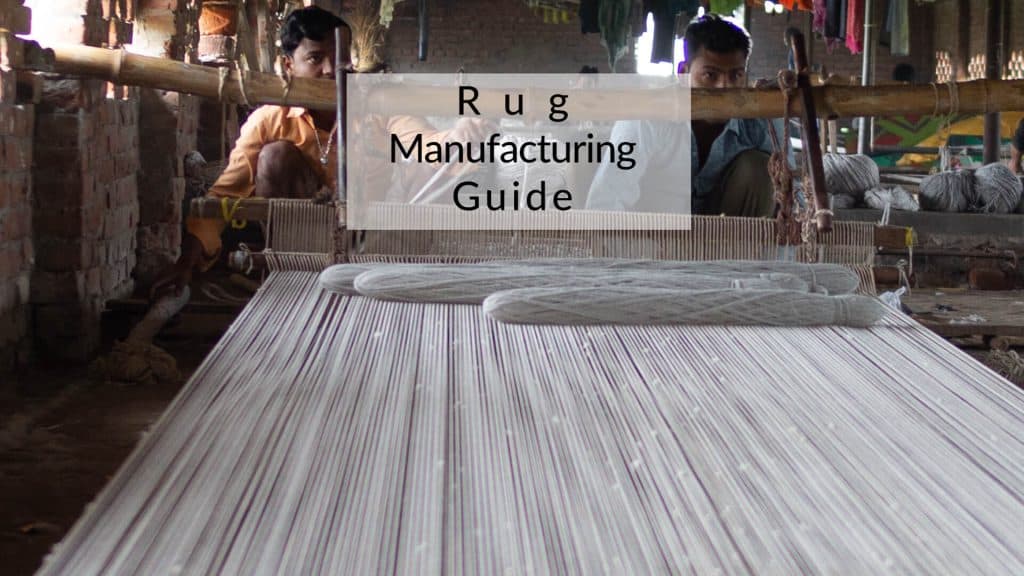

Hand-Knotted Rugs

Methods of hand-knotting date back to thousands of years ago. This ancient art takes the help of a unique wooden frame known as looms to weave by using the hands. At first, a vertical thread (warp) is tied onto the loom, followed by horizontal lines (weft). Knots are then tied on the vertical threads, which are then cut using a knife. An average weaver can tie about 10,000 knots in a day.

For this reason, the process takes a long time to finish, and it takes one month to make a rug. Natural fibers such as wool, cotton, etc., are used to make the rug. The products offer high quality and are highly expensive as the back design will be the same as the design of the front. Best rug manufacturers USA.

Hand-Tufted Rugs

A tufting gun containing a needle at its front is used to punch in and out of the fabric (canvas) stretched on a frame. Tufting-gun is a hand-operated tool where wool is mostly used for tufting. Once finished, the rugs are removed from the fabric, and a liquid latex or glue is used to coat the backside that prevents the yarn from unraveling. When compared to hand-knotting, this method takes less time to create rugs. will design The presented only on one side; the backside would be blank in tufted rugs. Best rug manufacturers USA.

Machine-made rugs

A machine called ‘power loom’ is used to weave the rug, which is run by electricity and uses synthetic fibers to produce wigs. They are the quickest way and speed up the weaving process. Not much skill is required –when compared to Hand-knotted Rugs. Best rug manufacturers USA.