Loom Knotted Rug: A Complete Guide: 16th Century brought the process of rug making to international stardom. Rugs and Carpets were seen as an accessory of status. Manufactured from the finest silks and the most skilled workers, carpet making was a celebrated art. The 21st century further pushed the notions of these heavy-duty textile products. Rugs and Carpets were no longer associated with the position in the society but were denoted as conduits of style, personality, and characteristics.

With the rise in the demand for carpets, the occupations surrounding them also evolved. Interior Boutique showroom, Design Showrooms, Rug Specialists, etc., became popular. With the advent of technology, replaced manual laborers with machines. These power looms can make a machine-knotted rug within hours, making them significantly cheaper. The quality, however, is more acceptable with handcrafting, where everything is monitored ideally. This is why handloom products survived while power loom produces affordable alternatives, but nowhere near the handloom quality.

However, certain institutions remain that use a handloom to create loom knotted custom rug. Although the price is higher, they believe in the product quality and the preservation of handcrafted artistry.

What are Loom Knotted Custom Rug, and How are They Made?

Loom Knotted custom rug are knotted rugs that are created on a loom. Currently, there exist two different kinds of looms. Power-looms are operated with the help of computers. A design is fed into the system, which translates to the rug. Since the whole operation is mechanical, the carpets produced are more efficient and cheaper. However, I cannot vouch for the quality.

Hand loom Knotted custom rug are made on a structure known as a handloom. It is a wooden frame on which yarns are strung vertically. These yarns are called warps and work as a foundation for the rug. These threads are put together closely and spun at the end of the wooden bars to sustain tension. Another category of lines called weft is then interwoven with warps horizontally. These yarns are responsible for etching out the design and the pattern.

Hand loom Knotted rug are made on a structure known as a handloom. It is a wooden frame on which yarns are strung vertically. These yarns are called warps and work as a foundation for the rug. These threads are put together closely and spun at the end of the wooden bars to sustain tension. Another category of lines called weft is then interwoven with warps horizontally. These yarns are responsible for etching out the design and the pattern.

The wefts are moved alternatively, allowing the warps to pass through. These warps are attached to a cylindrical shuttle. When the weft is raised, the shuttle is passed through. The wefts are then combed again and raised again, though the different wefts have changed positions this time. The warp is then passed through alternatively and knotted at each edge. The process happens in three stages; shedding, picking, and beating. The shedding procedure allows the wefts to be separated, and picking helps to interlace the warps, and beating encloses the warps tightly. The process is repeated continuously to produce the final product.

Every weft is intertwined with the warps row by row and knotted at each intersection. The thickness of the cylindrical rod on which warps are attached determines the height of the pile. This whole process is excruciatingly cumbersome and can take up to months to finish. A handloom can be operated by four or more workers at a time, decreasing the estimated production time.

Materials Associated

Though these loom knotted rug can be made of almost all fabrics, the generously used ones are bamboo viscose, wool, natural silk, and cotton. Not only do they have a high tension property, but they are easier to work with. Other fibers such as linen, polyester, etc., are also being used because they are softer and much smoother.

The Variance In Design

The designs associated with loom knotted custom rug are quite more straightforward. Monotones are the easiest to achieve. At best, the geometrical patterns or stripes and dots are accomplished. Intricate designs such as floral or an exact image are hard to engrave within and require unparalleled expertise and considerably more time. Since the process is essentially done with hands, every rug carries a unique pattern, although the base design is essentially the same.

Quality and Durability

Loom Knotted custom rug are probably the strongest of all carpet types. This is because of their dense nature. The density of loom knotted custom rugs depends not on their weight but the number of knots. The thinner the threads are, the more knots would be present. Thus the durability factor would increase. On average, an 8’ X 10’ rug carries 16 million knots, thus making it the strongest. These carpets are the best for areas that receive significant foot traffic, such as a drawing or living room.

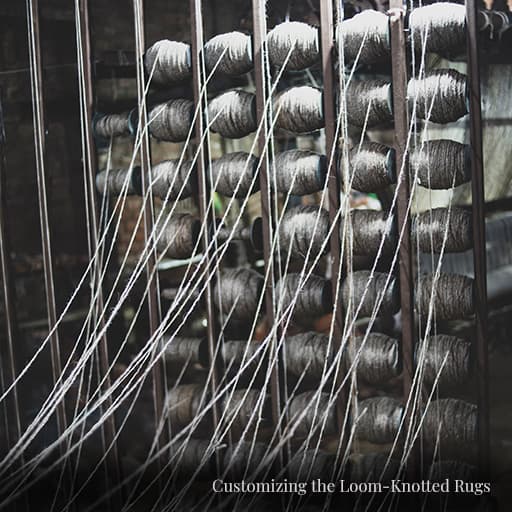

Customizing the Loom Knotted Rug

Just like any carpet or rug, loom knotted rug can be customized. Must note that using a handloom does not necessarily grant it any virtue. It just makes the production quicker. Hence achieves the benefits of knotted rugs faster in the case of less complicated designs. These rugs can be easily customized.

For customizing, the material needs to be decided on. As mentioned, natural fibers of wool, silk, cotton, and synthetic fibers such as linen, polyester, nylon can be used. Not only those, but recyclable yarns such as 100% can also use PET yarn can also be used to make loom knotted rug. These rugs can be made in loop piles, cut piles, or a mixture of both. The size is not a significant factor and can be altered without any hassle.

Before their looming, they can be dyed in any color required. Once they are dyed, they are dried under the sunlight, imparting them a vibrant color scheme. Should note that should dye only a small batch of yarn should be stained to maintain uniformity within the color.

These yarns are then woven into a design. Simpler designs do not require much time. However, as the intricacy and detailing within the pattern increases, the time consumed to produce it also increases. Therefore, this method is suitable only for a chosen few geometrical and symmetrical patterns.

Before a wholesale production of the loom knotted custom rug, a sample of both the colored fabric and the finished product is sent for approval. Only when the client accepts the quality and the color palette, the manufacturing is taken to scale. Ensures that the customer gets the best quality loom knotted custom rugs and carpets which meet all their requirements.

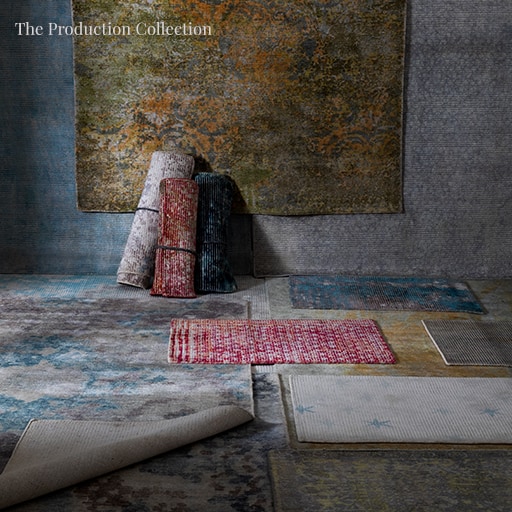

The Production Collection

MAT The Basics is a legacy name and has been operating since the 1940s. Their experience within the rug and carpet industry has garnered a unique nuance and taste for their loom knotted custom rugs. They offer wholesale distribution services to major brands across the globe. They also provide the service of customization within the loom knotted rug.

MAT The Basic’s loom knotted custom rug collection includes lines such as Bamboo Platinum and Akron, made out of Bamboo Viscose is smooth and silky hand-loomed carpets with yarns dyed in almost all different shades. Their other collection, Nile, mixes New Zealand wool with various colors to create a masterpiece with symmetrical designs. All of these rugs come in different sizes and can be customized as well. At present, they feature a range of collection lines.